CHINA J-VALVES Offers Various High-quality I ndustrial Ball Valves

J-VALVES, a distinguished professional ball valve manufacturer rooted in China, takes pride in its extensive product portfolio. Our offerings span a wide range, including trunnion-mounted ball valves, floating ball valves, high-temperature ball valves, high-pressure ball valves, metal-sealed ball valves, ultra-low temperature ball valves, DBB ball valves, Three-way And Four-way Ball Valve, and fully welded ball valves. Each product is a testament to our commitment to precision engineering and reliable performance. Meticulously crafted, they are designed to not only meet but exceed the most stringent industrial demands, ensuring stable operation even under extreme conditions. This enables us to provide our clients with high-value services and makes our valves widely sought-after in industries.

Product Category

Contact Us

Pressure class: 150LB ~ 2500LB (PN20 ~ PN420)

Temperature range: -196℃ ~ 540℃

Materials:

Valve body: WCB, CF8, CF8M, A105, F304, F316, etc.

Ball: F304, F316, Inconel and other alloy materials

Valve stem: 17-4PH, F316, Inconel, etc.

Sealing material: Metal seal (STL, Inconel and other cemented carbides)

Connection type: Flange connection (RF, RTJ)

Operation mode: Electric (on-off type, regulating type)

Design standards: ASME B16.34, API 6D, API 608

Testing standards: API 598, API 6D, ISO 5208

Face-to-face dimensions: In compliance with ASME B16.10 standard

-

J-VALVES

Hot Products

News

What Is A Double Block And Bleed (DBB) Trunnion Ball Valve?

In high-risk industrial applications such as oil & gas, petrochemical, and pipeline transportation systems, safety and isolation reliability are critical. One valve design widely recognized for meeting these stringent requirements is the Double Block and Bleed (DBB) Trunnion Ball Valve. This article

Read More

Trunnion Ball Valve Components: A Comprehensive Breakdown

Trunnion ball valves are essential components in industrial systems where reliability, precision, and durability are paramount. These valves are commonly used to control the flow of liquids or gases in pipelines and are distinguished by their trunnion-mounted ball design, which provides support to t

Read More

How To Choose The Right Trunnion Ball Valve Manufacturer: Key Criteria

When selecting a manufacturer for trunnion ball valves, the right decision can significantly impact the performance, safety, and longevity of your system. Trunnion ball valves are designed to handle high-pressure applications and provide excellent sealing, and the quality of the valve depends heavil

Read More

Top Entry Vs Side Entry Trunnion-Mounted Ball Valves: Installation Guide

Trunnion-mounted ball valves are essential components in industrial systems, offering reliable control of high-pressure fluids and gases. The design of the trunnion-mounted ball valve comes in two main configurations: top entry and side entry. Understanding the differences between these two designs

Read More

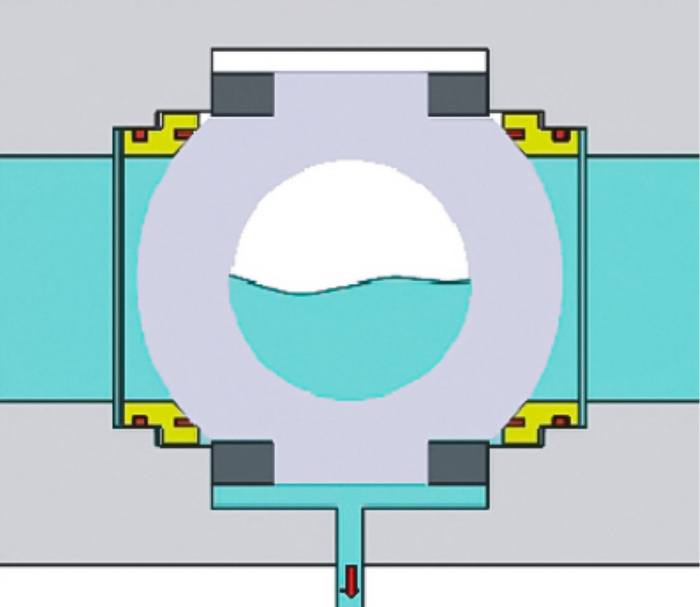

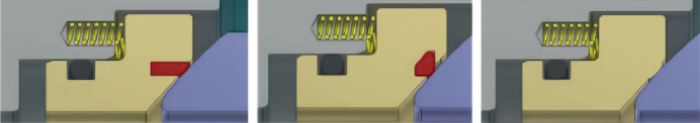

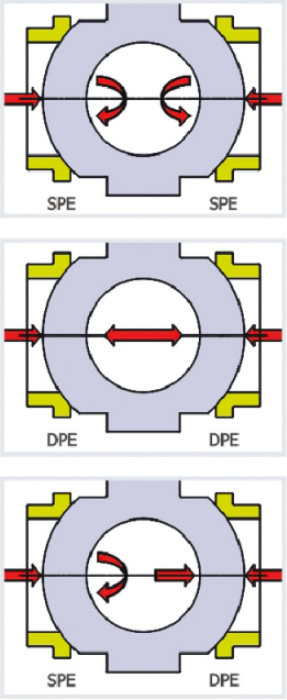

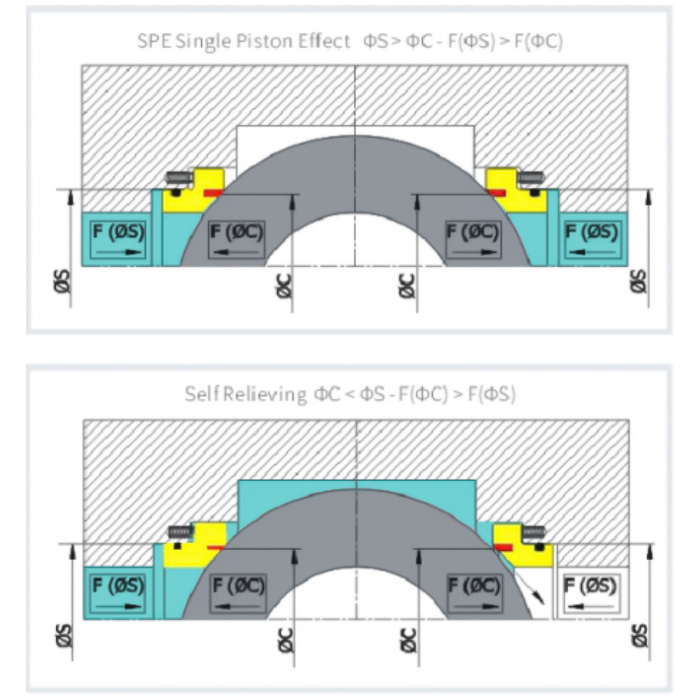

Double Piston Effect

Double Piston Effect