Pneumatic Forged Steel Flange Trunnion Ball Valve

Pressure Rating: 150LB~2500LB (PN20~PN420)

Temperature Range: -20℃ to +180℃

Materials:

Valve Body: Forged Steel (e.g., ASTM A105)

Valve Ball: Stainless Steel (e.g., 316 Stainless Steel)

Valve Stem: Stainless Steel (e.g., 316 Stainless Steel)

Sealing Material: PTFE, RPTFE

Connection Type: Flanged Connection (RF)

Operation Mode: Pneumatic Operation

Design Standards: API 6D, ASME B16.34

Testing Standards: API 598

End-to-End Dimensions: Compliant with ASME B16.10 Standard

Cryogenic Stainless Steel Ball Valve

Pressure Rating: 150LB~2500LB(PN20~PN420)

Temperature Range: -196℃ to +120℃(it varies depending on the specific materialand working conditions)

Materials:

Valve Body: 316 Stainless Steel

Valve Ball: 316 Stainless Steel

Valve Stem: 316 Stainless Steel

Sealing Material: PTFE, RPTFE

Connection Type: Flanged Connection (RF)

Operation Mode: Manual (Handwheel Operation), Pneumatic, Electric

Design Standards: API 6D, ASME B16.34

Testing Standards: API 598, ISO 5208

End-to-End Dimensions: Compliant with ASME B16.10 Standard

Duplex Steel 3PC Trunnion Flange Ball Valve

Pressure Rating: 150LB~2500LB(PN20~PN420)

Temperature Range: -46℃ to +200℃(it varies depending on the specific materialand working conditions)

Materials:

Valve Body: Super Duplex Stainless Steel (2507/S32750)

Valve Ball: Super Duplex Stainless Steel (2507/S32750)

Valve Stem: Super Duplex Stainless Steel (2507/S32750)

Sealing Material: PTFE, RPTFE

Connection Type: Flanged Connection (RF)

Operation Mode: Manual (Handwheel Operation), Pneumatic, Electric

Design Standards: API 6D, ASME B16.34

Testing Standards: API 598, ISO 5208

End-to-End Dimensions: Compliant with ASME B16.10 Standard

Forged Steel Fully Welded Ball Valve with Sleeves

Pressure Rating: 150LB ~ 2500LB (PN20 ~ PN420)

Temperature Range: -46℃ ~ +200℃ (standard type); high/low temperature types are customizable

Materials:

Valve Body/Bonnet: Forged steel such as A105N, LF2, F304, F316, F51 duplex steel

Ball: A105+ENP, F304, F316, F51

Stem: 17-4PH, F304, F316

Seat Seal: PTFE, RPTFE, PEEK, NYLON, DEVLON

Sleeve Material: Carbon steel (epoxy coated) or stainless steel

Connection Type: Butt weld ends (BW) conforming to ASME B16.25

Operation Mode: Manual (worm gear operator), pneumatic, electric, electro-pneumatic, electro-hydraulic

Design Standards: API 6D, ASME B16.34, ISO 14313

Testing Standards: API 6D, API 598, ISO 5208

Fire-safe Standards: API 607, API 6FA

Leakage Class: Zero leakage (FCI 70-2 Class VI)

Electric Fully Welded Trunnion Ball Valve

Pressure Rating: 150LB ~ 2500LB (PN16 ~ PN420)

Temperature Range: -40℃ ~ +200℃ (high/low temperature models customizable)

Materials:

Valve Body: ASTM A105, A350 LF2, A182 F304/F316

Ball: ASTM A182 F304/F316 + Hardening Treatment

Valve Stem: ASTM A182 F304/F316, 17-4PH

Sealing Materials: PTFE, RPTFE, PEEK, Metal Seal

Connection Method: Butt Weld (BW), Socket Weld (SW)

Operation Mode: Electric (On-off/Regulating Type), Manual (Backup)

Design Standards: API 6D, ASME B16.34, ISO 14313

Testing Standards: API 598, API 6D, ISO 5208

Face-to-face Dimensions: API 6D, ASME B16.10

Cryogenic Trunnion Mounted Ball Valves

Pressure rating: 150LB ~ 2500LB (PN20 ~ PN420)

Temperature range: -196℃ ~ +120℃

Materials:

Valve body: LF2, LF3, 304, 316, 316L, F304, F316, F316L

Ball: 304, 316, 316L

Stem: 304, 316, Inconel 718

Valve seat seal: PCTFE, DEVLON V, PEEK

Stem seal: Low-temperature packing (e.g. PTFE + flexible graphite composite)

Connection type: Flanged (RF/RTJ), Welded end (BW/SW)

Operation mode: Manual (worm gear), Pneumatic, Electric, Hydraulic

Design standards: ASME B16.34, API 6D, ISO 14313, BS 6364

Testing standards: API 598, API 6D, ISO 5208, BS 6364

Face-to-face dimensions: ASME B16.10, API 6D

Electric Metal Sealed Trunnion Flange Ball Valve

Pressure class: 150LB ~ 2500LB (PN20 ~ PN420)

Temperature range: -196℃ ~ 540℃

Materials:

Valve body: WCB, CF8, CF8M, A105, F304, F316, etc.

Ball: F304, F316, Inconel and other alloy materials

Valve stem: 17-4PH, F316, Inconel, etc.

Sealing material: Metal seal (STL, Inconel and other cemented carbides)

Connection type: Flange connection (RF, RTJ)

Operation mode: Electric (on-off type, regulating type)

Design standards: ASME B16.34, API 6D, API 608

Testing standards: API 598, API 6D, ISO 5208

Face-to-face dimensions: In compliance with ASME B16.10 standard

Trunnion Mounted Fully Welded Ball Valve

Pressure Rating: 150LB~2500LB(PN20~PN420)

Temperature Range: -46℃ to +200℃(it varies depending on the specific materialand working conditions)

Materials:

Valve Body: ASTM A105 Carbon Steel

Valve Ball: Hardened Stainless Steel (e.g., 410 Stainless Steel)

Valve Stem: Stainless Steel (e.g., 316 Stainless Steel)

Sealing Material: PTFE, RPTFE

Connection Type: Butt Weld Connection (BW)

Operation Mode: Manual (Gearbox Operation), Pneumatic, Electric

Design Standards: API 6D, ASME B16.34

Testing Standards: API 598

End-to-End Dimensions: Compliant with ASME B16.10 Standard

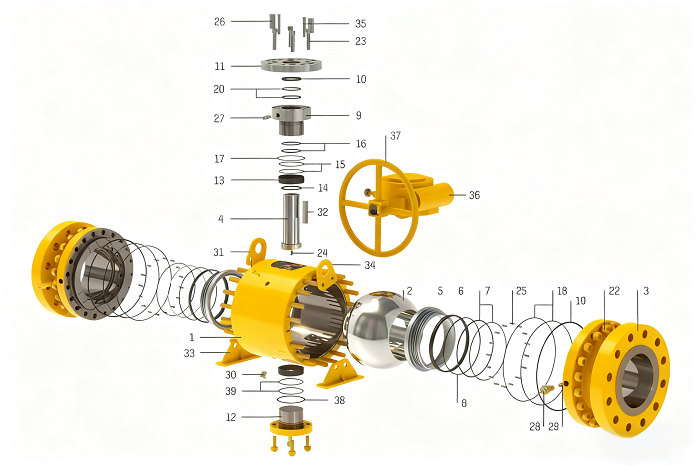

3PC Forged Steel Trunnion Flanged Ball Valves

Pressure Rating: 150LB~2500LB(PN20~PN420)

Temperature Range: -46℃ to +200℃(it varies depending on the specific materialand working conditions)

Valve Body: Forged Steel (e.g., ASTM A105)

Valve Ball: Hardened Stainless Steel (e.g., 410 Stainless Steel)

Valve Stem: Stainless Steel (e.g., 316 Stainless Steel)

Sealing Material: PTFE, RPTFE

Connection Type: Flanged Connection (RF)

Operation Mode: Manual (Handwheel Operation), Pneumatic, Electric

Design Standards: API 6D, ASME B16.34

Testing Standards: API 598

End-to-End Dimensions: Compliant with ASME B16.10 Standard

3PC High-temperature And High-pressure Trunnion Ball Valve

Pressure Rating: 150LB ~ 2500LB (PN20 ~ PN420)

Temperature Range: -46℃ ~ +650℃

Materials:

Valve Body: A105N, F304, F316, F22, F91

Ball: F304, F316, F6a (surface hardening available)

Stem: 17-4PH, F304, F316

Seal Materials: PTFE, RPTFE, PEEK, Metal Seal (Stellite/Chromium Carbide)

Connection Types: Flanged (RF/RTJ), Butt Welded (BW)

Operation Modes: Manual (worm gear operated), Pneumatic, Electric, Electro-hydraulic

Design Standards: API 6D, ASME B16.34, ISO 17292

Testing Standards: API 598, API 6D, ISO 5208

Face-to-face Dimensions: Compliant with ASME B16.10 and API 6D standards

Seat Structure: Double Piston Effect (DPE) or Single Piston Effect (SPE)

API6D WCB Fully Welded Ball Valve

Pressure Rating: 150LB~2500LB(PN20~PN420)

Temperature Range: -46℃ to +200℃(it varies depending on the specific materialand working conditions)

Materials:

Valve Body: ASTM A216 WCB

Valve Ball: Hardened Stainless Steel (e.g., 410 Stainless Steel)

Valve Stem: Stainless Steel (e.g., 316 Stainless Steel)

Sealing Material: PTFE, RPTFE

Connection Type: Butt Weld Connection (BW)

Operation Mode: Manual (Handwheel Operation), Pneumatic, Electric

Design Standards: API 6D, ASME B16.34

Testing Standards: API 598, ISO 5208

End-to-End Dimensions: Compliant with ASME B16.10 Standard

J-VALVES CHINA Offers Various High-quality I ndustrial Ball Valves

J-VALVES CHINA, as a widely recognized high-quality manufacturer of industrial ball valves, supplies various ball valves for the global industry. In the petrochemical industry, the floating ball valve can accurately regulate the medium with its exquisite design to ensure the smooth operation of the pipeline; the trunnion mounting ball valve has strong bearing capacity to cope with high-temperature and high-pressure environments and assist large-scale refining. During the natural gas transmission, the fully welded ball valve achieves zero leakage and excellent weather resistance by seamless welding to protect the gas supply network. In the shipbuilding field, the top entry ball valve is easy to maintain, suitable for multiple systems and reduces the downtime for maintenance; the DBB ball valve(Double block and bleed ball valve) has unique functions and prevents cross-contamination of materials in industries such as fine chemicals and pharmaceuticals. Relying on exquisite craftsmanship, strict quality control and innovation capabilities, from material selection to the application of cutting-edge technologies, it creates durable and reliable ball valves for customers.

Ball Valves Product Categories

1PC Flanged Floating Ball Valve

2PC Flanged Floating Ball Valve

3PC Flanged Floating Ball Valve

Threaded End Floating Ball Valve

Socket Weld (SW) Floating Ball Valve

Butt Weld (BW) Floating Ball Valve

Three-Way Floating Ball Valve

High Platform Floating Ball Valve

Metal-Seated Floating Ball Valve

Cryogenic Floating Ball Valve

Forged Floating Ball Valve

Stainless Steel Floating Ball Valve

Cast Floating Ball Valve

High-Pressure Floating Ball Valve

2PC Flanged Trunnion Mounted Ball Valves

3PC Side-Entry Flanged Trunnion Mounted Ball Valves

Metal-Seated Trunnion Mounted Ball Valves

Top-Entry Flanged Trunnion Mounted Ball Valves

High-Temperature Trunnion Mounted Ball Valves

High-Pressure Trunnion Mounted Ball Valves

Socket Weld (SW) Trunnion Mounted Ball Valves

Butt Weld (BW) Trunnion Mounted Ball Valves

Forged Trunnion Mounted Ball Valves

Cast Trunnion Mounted Ball Valves

Line Trunnion Mounted Ball Valves

Full Bore Trunnion Mounted Ball Valves

Reduced Bore Trunnion Mounted Ball Valves

Cryogenic Trunnion Mounted Ball Valves

DBB Flanged Floating Ball Valve

DBB Flanged x Threaded Floating Ball Valve

DBB Threaded Floating Ball Valve

DBB Flanged Trunnion Mounted Ball Valve

DBB Ferrule Ball Valve

DBB Cryogenic Ball Valve

DBB High-Pressure Ball Valve

Double Ball Ball Valve

Full Bore DBB Flanged Ball Valve

Reduced Bore DBB Flanged Ball Valve

SBB Ball Valve

SBB Flanged x Threaded Ball Valve

SBB Threaded Ball Valve

Double Block and Bleed Ball Valve

Single Block and Bleed Ball Valve

Cryogenic Flanged Floating Ball Valve

Cryogenic Threaded Floating Ball Valve

Cryogenic Welded Ball Valve

Cryogenic Top-Entry Ball Valve

Cryogenic Fully Welded Ball Valve

Cryogenic Trunnion Mounted Ball Valve

Cryogenic DBB Ball Valve

Cryogenic Cast Ball Valve

Cryogenic Forged Ball Valve

Cryogenic Side-Entry Ball Valve

Bi-Directional Sealing Cryogenic Ball Valve

Cryogenic Stainless Steel Ball Valve

Cryogenic Extended Stem Ball Valve

Fire-Safe Cryogenic Ball Valve

Fully Welded Flanged Ball Valve

Fully Welded Ball Valve

Extended Stem Fully Welded Ball Valve

Underground Fully Welded Ball Valve

Natural Gas Fully Welded Ball Valve

Gas-Hydraulic Actuated Fully Welded Ball Valve

Floating Fully Welded Ball Valve

Trunnion Mounted Fully Welded Ball Valve

DIB-1 Fully Welded Ball Valve

Anti-Static Fully Welded Ball Valve

Fire-Safe Design Fully Welded Ball Valve

Threaded End Top-Entry Ball Valve

Socket Weld (SW) Top-Entry Ball Valve

Butt Weld (BW) Top-Entry Ball Valve

Floating Top-Entry Ball Valve

Cryogenic Floating Ball Valve

Trunnion Mounted Top-Entry Ball Valve

Cryogenic Top-Entry Trunnion Mounted Ball Valve

Full Bore Top-Entry Ball Valve

Forged Top-Entry Ball Valve

Cast Top-Entry Ball Valve

Anti-Static Top-Entry Ball Valve

Fire-Safe Top-Entry Ball Valve

Three-Way Floating Ball Valve

Three-Way Threaded End Ball Valve

Three-Way Trunnion Mounted Ball Valves

Three-Way Flanged Ball Valve

Y-Port Three-Way Ball Valve

T-Port Three-Way Ball Valve

L-Port Three-Way Ball Valve

Three-Way Fire-Safe Ball Valve

Three-Way Metal-Seated Ball Valve

Four-Way Floating Ball Valve

Four-Way Trunnion Mounted Ball Valves

Four-Way Flanged Ball Valve

Forged Three-Way/Four-Way Ball Valve

Cast Three-Way/Four-Way Ball Valve

Pneumatic Floating Ball Valve

Pneumatic Trunnion Mounted Ball Valves

Pneumatic Flanged Ball Valve

Pneumatic Threaded End Ball Valve

Pneumatic Welded Ball Valve

Pneumatic High-Temperature Ball Valve

Pneumatic Three-Way Ball Valve

Pneumatic Cryogenic Ball Valve

Electric Floating Ball Valve

Electric Trunnion Mounted Ball Valves

Electric Flanged Ball Valve

Electric Threaded End Ball Valve

Electric Welded Ball Valve

Electric High-Temperature Ball Valve

Electric Three-Way Ball Valve

Electric Cryogenic Ball Valve

Professional Techincal Team

We boast a dedicated technical team specializing in ball valves, proficient in end-to-end design and R&D. With rapid turnaround for both 2D and 3D drawings, we deliver robust technical support for all engineering projects.

PRODUCTION SCOPE OF BALL VALVES

Why Choose J-VALVES BALL VALVES

Enhanced Operational Efficiency

Our ball valves provide precise control over liquid and gas flow, ensuring smooth process management and improved operational efficiency.

Increased Safety and Reliability

Designed to minimize leaks and meet stringent standards, our ball valves enhance safety and ensure reliable performance under extreme conditions.

Cost-Effective Maintenance

Durable and long-lasting, our ball valves reduce maintenance frequency and costs, minimizing operational disruptions and enhancing system longevity.

Long-Term Investment Benefits

Investing in our ball valves boosts system efficiency and reliability, offering significant long-term benefits and improved operational sustainability.

J-VALVES Ball Valve Main Design Standards

We have taken into account all the challenges you may encounter when selecting ball valve standards. J-VALVES provides ball valves compliant with a variety of design standards, including API, ASME, ISO, BS, JIS, DIN, GOST, etc. Meanwhile, we also have in-depth expertise in the specific standards of oil companies such as Shell and ADNOC.

API Standards

•API 6D - Specification for Pipeline Valves

•API 608 - Ball Valves, Flanged, Threaded and Welded Ends

•ASME B16.34 - Valves - Flanged, Threaded, and Welding End

ISO Standards

BS Standards

JIS Standards

•JIS B 2001 - Ball Valves for Industrial Use

•JIS B 2002 - Ball Valves for Piping

•JIS B 2003 - Test Methods for Ball Valves

DIN Standards

GOST Standards

J-VALVES Delivers Comprehensive Solutions to Your Ball Valve Challenges

J-VALVES are capable of providing full-range support for ball valve type selection, design and calculation, and premium-grade manufacturing. If you face any intractable technical or operational problems, please reach out to us, and our team will deliver specialized professional recommendations.