CHINA J-VALVES Offers Various High-quality I ndustrial Ball Valves

J-VALVES, a distinguished professional ball valve manufacturer rooted in China, takes pride in its extensive product portfolio. Our offerings span a wide range, including trunnion-mounted ball valves, floating ball valves, high-temperature ball valves, high-pressure ball valves, metal-sealed ball valves, ultra-low temperature ball valves, DBB ball valves, Three-way And Four-way Ball Valve, and fully welded ball valves. Each product is a testament to our commitment to precision engineering and reliable performance. Meticulously crafted, they are designed to not only meet but exceed the most stringent industrial demands, ensuring stable operation even under extreme conditions. This enables us to provide our clients with high-value services and makes our valves widely sought-after in industries.

Product Category

Contact Us

Pressure Rating: 150LB to 600LB (PN20 to PN100)

Temperature Range: -46℃ to +200℃

Materials:

Valve Body: 316 Stainless Steel

Valve Ball: 316 Stainless Steel

Valve Stem: 316 Stainless Steel

Sealing Material: PTFE, RPTFE, Metal Seat

Connection Type: Flanged Connection (RF), Butt Weld Connection (BW)

Operation Mode: Manual (Handwheel Operation), Pneumatic, Electric

Design Standards: API 6D, ASME B16.34

Testing Standard: API 598

End-to-End Dimensions: Compliant with ASME B16.10 Standard

-

J-VALVES

Hot Products

News

Technical Analysis of Cryogenic Ball Valve Applications: Addressing The Challenges of Extreme Environments

As critical fluid control equipment for special operating conditions, cryogenic ball valves are widely used in ultra-low temperature environments such as liquefied gas transportation, deep space exploration, liquid nitrogen and liquid hydrogen systems. The design and manufacturing of such valves mus

Read More

API/ISO/DIN Ball Valve Standards: Key Differences And Application Adaptation Guide

In the design, manufacturing, testing and application of ball valves, different international standard systems impose distinct requirements on the valves. API (American Petroleum Institute), ISO (International Organization for Standardization) and DIN (Deutsches Institut für Normung) are the three m

Read More

Comparison of International Standards for Ball Valves in The Oil And Gas Sector: Core Differences Between The API And ISO Systems

In the oil and gas industry, ball valves serve as critical fluid control equipment and are widely used for regulating and isolating various fluids. To ensure the safety, reliability and performance of ball valves under different operating conditions, multiple international standards have been establ

Read More

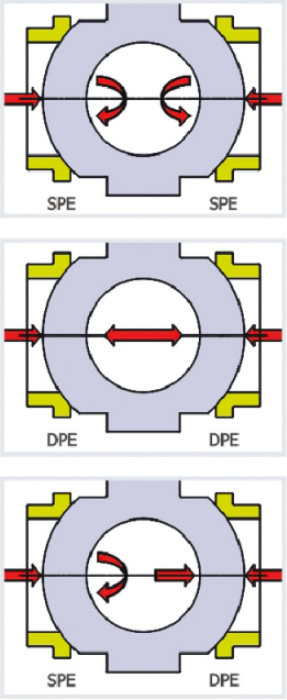

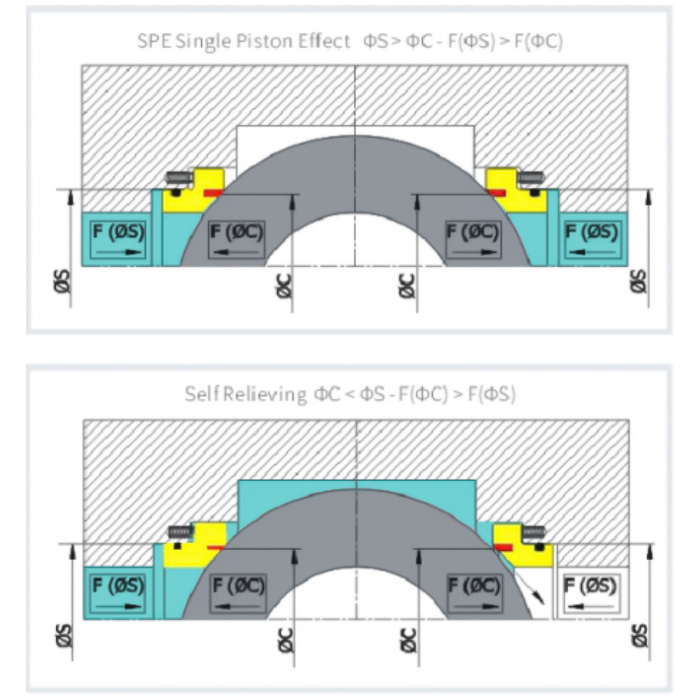

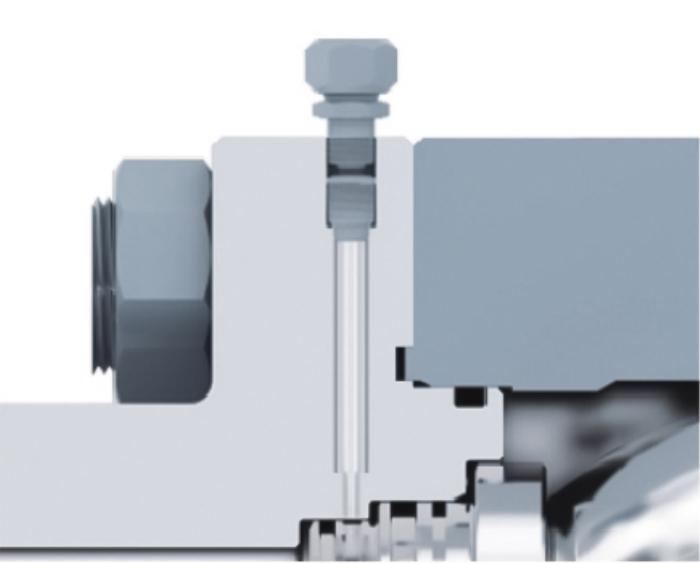

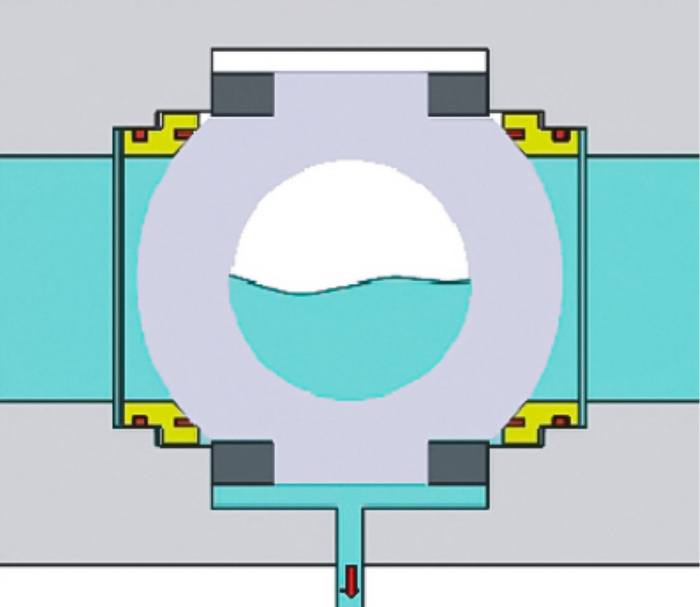

What Is A Double Block And Bleed (DBB) Trunnion Ball Valve?

In high-risk industrial applications such as oil & gas, petrochemical, and pipeline transportation systems, safety and isolation reliability are critical. One valve design widely recognized for meeting these stringent requirements is the Double Block and Bleed (DBB) Trunnion Ball Valve. This article

Read More