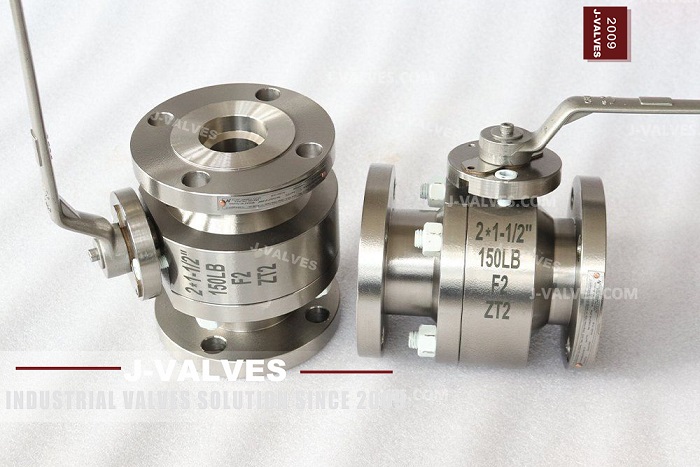

When selecting industrial valves, matching pressure ratings to your pipeline needs is non-negotiable. J-VALVES’2x1-1/2" flanged floating ball valves (2PC design) come in two common pressure classes: 150LB and 1500LB. Below, we break down their key differences to help you pick the right fit.

1. Pressure Rating: The Core Distinction

150LB Model: Designed for low-to-medium pressure systems (typically up to 285 PSI at 100°F, per ASME B16.34 standards). Ideal for general industrial pipelines, water treatment, or low-pressure chemical transfer.

1500LB Model: Built for high-pressure applications (up to 2900 PSI at 100°F). Suited for oil & gas pipelines, high-pressure hydraulic systems, or heavy-duty process plants.

2. Design & Durability

Both use J-VALVES’ 2PC flanged floating ball structure (easy maintenance, tight sealing), but the 1500LB version features:

Thicker body walls to withstand higher internal pressure

Reinforced flange connections (compliant with ASME B16.5 high-pressure standards)

Heavy-duty stem seals to prevent leakage under extreme pressure

3. Application Scenarios

Choose 150LB if:

Your system runs at low-to-moderate pressure (e.g., municipal water, light chemical lines)

You prioritize cost-effectiveness for standard operating conditions

Choose 1500LB if:

Your pipeline handles high-pressure fluids (e.g., crude oil, high-pressure steam)

You need compliance with heavy industrial safety standards

Final Verdict

J-VALVES’ 2x1-1/2" flanged floating ball valves deliver reliable performance—but match the pressure rating to your system’s needs: 150LB for standard use, 1500LB for high-pressure industrial applications.