CHINA J-VALVES Offers Various High-quality I ndustrial Ball Valves

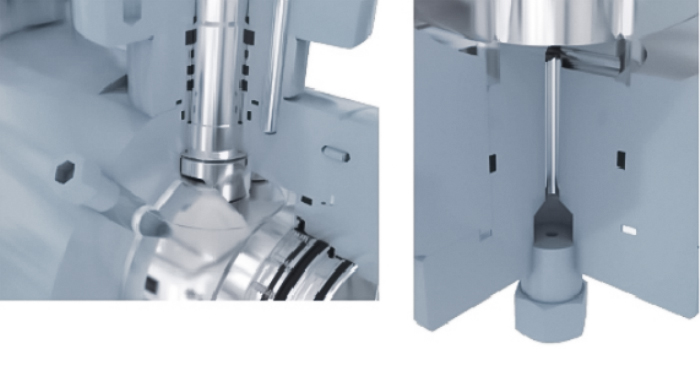

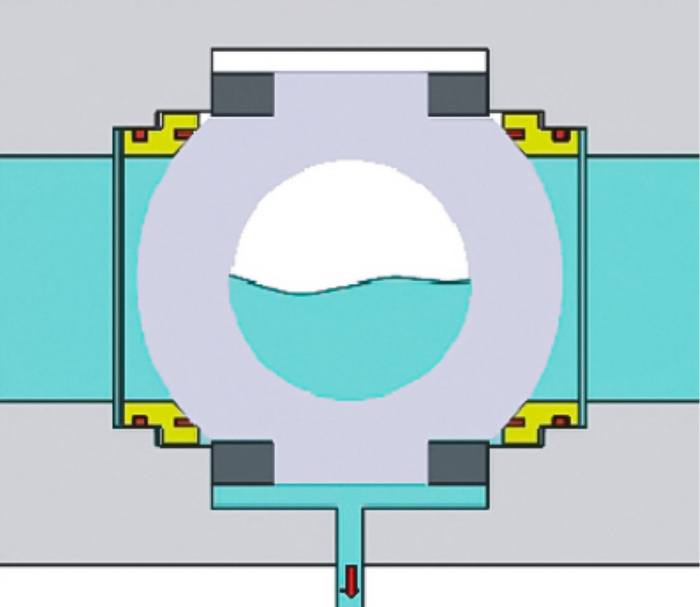

J-VALVES, a distinguished professional ball valve manufacturer rooted in China, takes pride in its extensive product portfolio. Our offerings span a wide range, including trunnion-mounted ball valves, floating ball valves, high-temperature ball valves, high-pressure ball valves, metal-sealed ball valves, ultra-low temperature ball valves, DBB ball valves, Three-way And Four-way Ball Valve, and fully welded ball valves. Each product is a testament to our commitment to precision engineering and reliable performance. Meticulously crafted, they are designed to not only meet but exceed the most stringent industrial demands, ensuring stable operation even under extreme conditions. This enables us to provide our clients with high-value services and makes our valves widely sought-after in industries.

Product Category

Contact Us

Pressure Class: 150LB to 2500LB (PN20 to PN420).

Temperature Range: -46℃ to +180℃.(specific range depends on sealing materials and working conditions)

Materials:

Valve Body: Carbon steel (A105), alloy steel

Ball: Stainless steel.

Stem: Stainless steel.

Sealing Material: PTFE, RPTFE, metal seal.

Connection Type: Flange connection (ASME B16.5/ASME B16.47), butt-weld connection (ASME B16.25)

Design Standards: API 6D

Testing Standards: API 598

Applicable Media: Oil, natural gas, water, steam, chemical media.

-

J-VALVES

Hot Products

News

Trunnion Ball Valves: Product Series And Technical Highlights

Trunnion ball valves are critical components in fluid control systems across a variety of industries, including oil and gas, chemical processing, water treatment, and power generation. These valves are known for their ability to handle high pressures and large volumes of fluid, making them indispens

Read More

Trunnion Type Ball Valves: Classification And Selection Basics

Trunnion type ball valves are critical components in industrial systems, particularly in applications requiring high-pressure control and flow regulation. These valves are specifically designed to handle large volumes of fluid and high-pressure systems, making them ideal for use in industries such a

Read More

Trunnion-Mounted Ball Valve Catalogue: Key Parameters To Note

Trunnion-mounted ball valves are vital components in various industries, especially in applications involving high pressure, temperature, and flow rates. These valves are specifically designed to control the flow of liquids, gases, and slurries in pipelines. They feature a ball that is supported by

Read More

Top-Entry Trunnion-Mounted Ball Valves: Key Features, Benefits, And Applications for Industrial Systems

Top-entry trunnion-mounted ball valves are widely used in industrial fluid control systems, providing excellent durability and performance in high-pressure and high-flow applications. Known for their robust design and ability to handle challenging operating conditions, these valves play a critical r

Read More