CHINA J-VALVES Offers Various High-quality I ndustrial Ball Valves

J-VALVES, a distinguished professional ball valve manufacturer rooted in China, takes pride in its extensive product portfolio. Our offerings span a wide range, including trunnion-mounted ball valves, floating ball valves, high-temperature ball valves, high-pressure ball valves, metal-sealed ball valves, ultra-low temperature ball valves, DBB ball valves, Three-way And Four-way Ball Valve, and fully welded ball valves. Each product is a testament to our commitment to precision engineering and reliable performance. Meticulously crafted, they are designed to not only meet but exceed the most stringent industrial demands, ensuring stable operation even under extreme conditions. This enables us to provide our clients with high-value services and makes our valves widely sought-after in industries.

Product Category

Contact Us

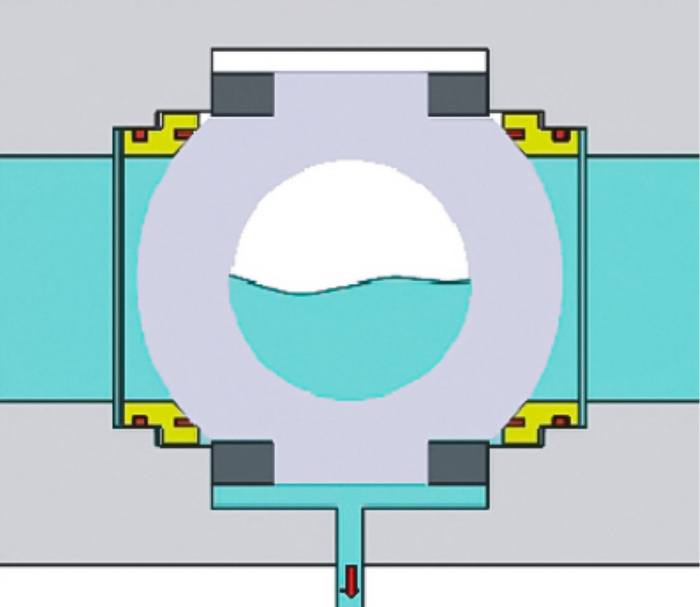

Pressure Rating: 150LB~2500LB (PN20~PN420)

Temperature Range: -46℃ to +200℃(it varies depending on the specific material and working conditions)

Materials:

Valve Body: 316 Stainless Steel

Valve Ball: 316 Stainless Steel

Valve Stem: 316 Stainless Steel

Sealing Materials: PTFE, RPTFE

Connection Type: Flanged Connection (RF)

Operation Mode: Manual (Handwheel Operation), Pneumatic, Electric

Design Standards: ASME B16.34, API 608, API 6D

Testing Standards: API 598, ISO 5208

End-to-End Dimensions: Compliant with ASME B16.10 Standard

-

J-VALVES

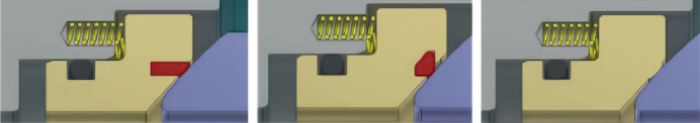

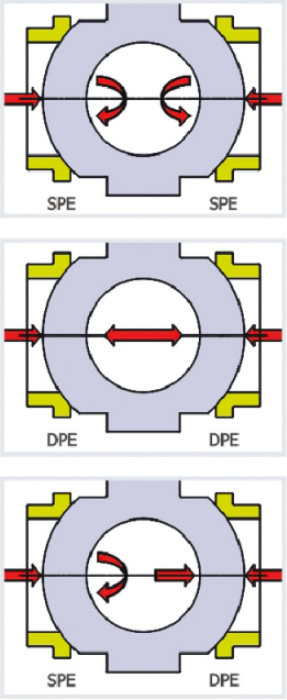

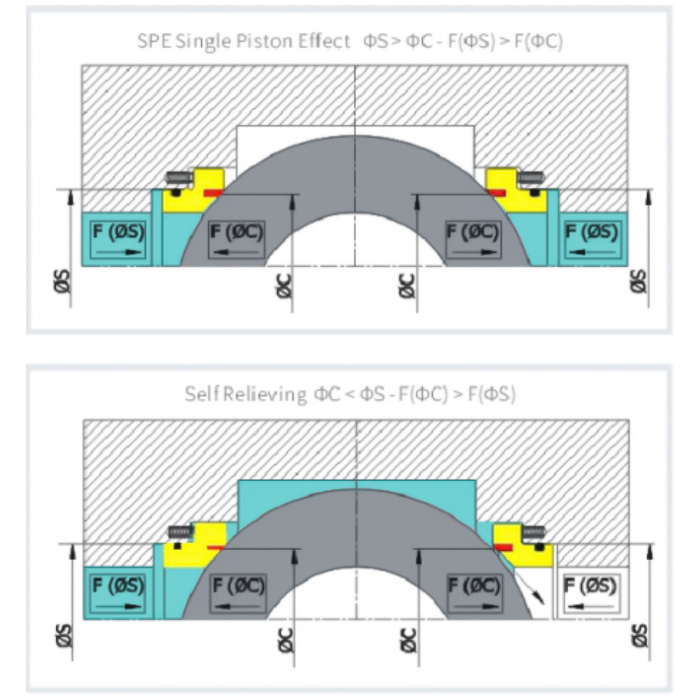

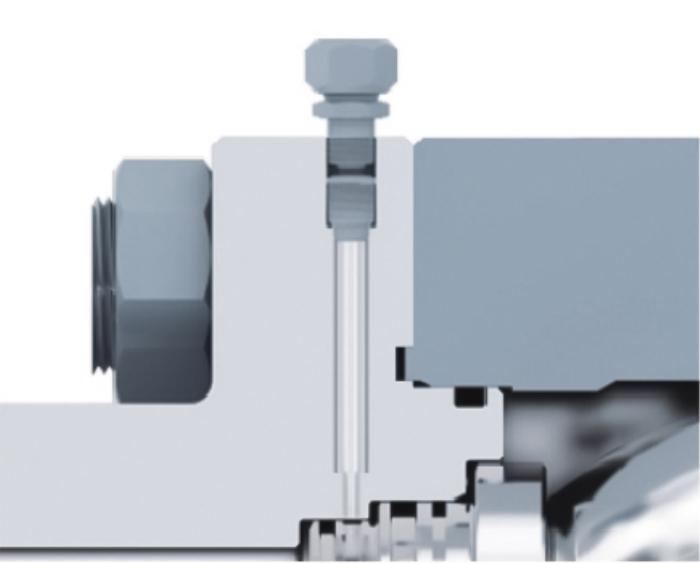

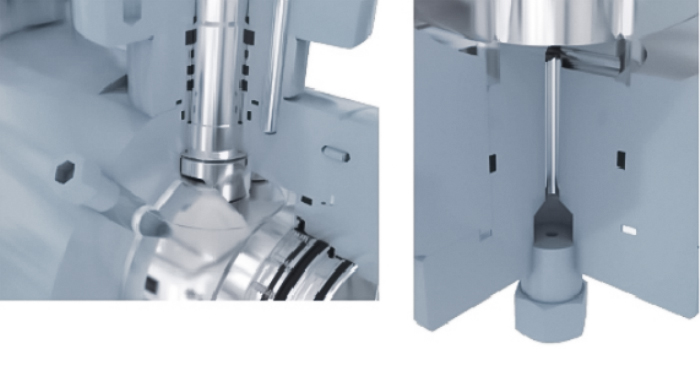

How To Optimize Torque Management in Trunnion Ball Valves

Trunnion ball valves are widely used in various industrial applications due to their ability to handle high pressures and large flow rates. One of the key factors in ensuring the efficient operation of these valves is proper torque management. Optimizing torque management not only enhances the valve

Read More

How Can The Reliability of Fully Welded Ball Valves Be Achieved under Harsh Working Conditions

Impact of Severe Operating Conditions on Fully Welded Ball ValvesHigh-temperature environments: High temperatures may lead to a decline in material performance, such as reduced strength and accelerated creep, which in turn affect the sealing performance and structural integrity of the valve.High-pre

Read More

Enhancing The Corrosion Resistance of Trunnion Ball Valves for Complex Working Conditions

Trunnion ball valves are characterized by their robust design and ability to handle high pressures and temperatures. The Trunnion design provides stability and reduces the operating torque required to rotate the ball. These valves are typically used in applications where tight sealing and high durab

Read More

Efficient Application of Trunnion Ball Valves in Industrial Fluid Control

In modern industrial production, fluid control is a key link to ensure the smooth progress of the production process. As an efficient and reliable fluid control device, the ear trunnion ball valve is widely used in multiple fields such as petroleum, chemical engineering, natural gas and water treatm

Read More