CHINA J-VALVES Offers Various High-quality I ndustrial Ball Valves

J-VALVES, a distinguished professional ball valve manufacturer rooted in China, takes pride in its extensive product portfolio. Our offerings span a wide range, including trunnion-mounted ball valves, floating ball valves, high-temperature ball valves, high-pressure ball valves, metal-sealed ball valves, ultra-low temperature ball valves, DBB ball valves, Three-way And Four-way Ball Valve, and fully welded ball valves. Each product is a testament to our commitment to precision engineering and reliable performance. Meticulously crafted, they are designed to not only meet but exceed the most stringent industrial demands, ensuring stable operation even under extreme conditions. This enables us to provide our clients with high-value services and makes our valves widely sought-after in industries.

Product Category

Contact Us

-

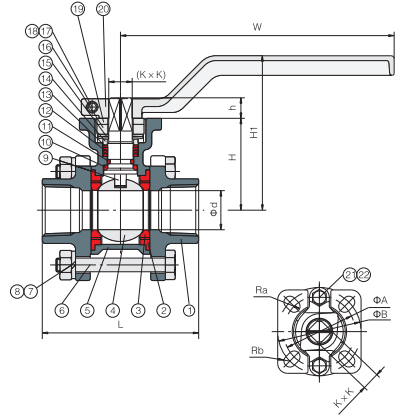

Q11F

-

J-VALVES

Trunnion Ball Valves: The Preferred Choice for High-Pressure Applications

Understanding Trunnion-Mounted Ball ValvesDesign and FunctionTrunnion-mounted ball valves are designed to handle high pressures and large flow rates, making them suitable for critical industrial applications. The key design feature is the trunnion or ear-axis mechanism, which supports the ball and r

Read More

Materials And Design of Ultra-Low Temperature Trunnion Ball Valves

In the field of transportation and control of cryogenic media such as liquefied natural gas (LNG), liquid oxygen, and liquid nitrogen, ultra-low temperature trunnion ball valves have broad application prospects. Under cryogenic working conditions, such valves not only need to have reliable sealing p

Read More

Intelligent Control And Remote Monitoring System for Pneumatic Ball Valves

Pneumatic ball valves are widely used in various industrial applications due to their reliability, ease of operation, and ability to provide precise flow control. With the advancement of technology, the integration of intelligent control and remote monitoring systems has become increasingly importan

Read More

Key Technologies And Application Value of High-Performance Trunnion Mounted Ball Valves

What is a Trunnion Mounted Ball Valve?A trunnion mounted ball valve adopts an upper and lower support bearing design, which keeps the ball stable in high-pressure environments and prevents displacement caused by medium pressure. Its core advantages include:Low operating torqueReliable high-pressure

Read More