In industrial pipeline systems, "leakage", "jamming", and "short service life" are almost unavoidable pain points for every purchaser, engineer, and maintenance personnel. Especially under working conditions of high pressure, high corrosion, or continuous operation, even a 1% failure of a floating ball valve assembly may cause the entire production system to shut down. But the question is—why do ball valves that seem identical on the market have such huge differences in actual performance?

Faced with these common troubles, more and more enterprises are turning their attention to J-VALVES assembled component floating ball valves. So, can this compact-structured and process-stable floating ball valve assembly really solve your pain points?

I. Why Do Many Floating Ball Valves Often Leak? Where Exactly Is the Problem?

The root cause of most pipeline leaks actually comes from two aspects:

Insufficient assembly precision, preventing "true fitting" of the seal

Many ball valves on the market look sleek, but their internal assembly precision is poor. Even micron-level deviations between the ball, valve seat, and valve stem can cause uneven force on the sealing surface, leading to chronic leakage.

Uneven processing of the valve body and connecting components

Under high-pressure working conditions, if the roughness or thickness of the flange surface is not well controlled, the force on the bolts will be uneven, ultimately resulting in reduced sealing performance.

II. How Do J-VALVES Assembled Component Floating Ball Valves Solve These Industry Pain Points?

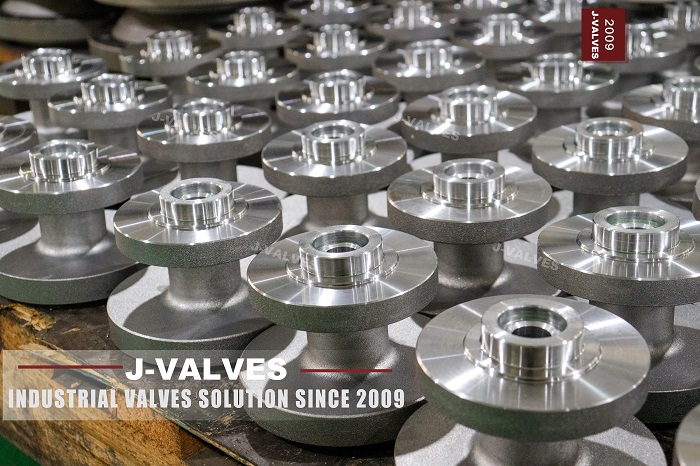

From the photos you provided, it can be seen that J-VALVES adopts highly consistent processing standards in the valve seat, valve body, and flange assembly areas—showing stable and batch-consistent industrial-grade precision as a whole.

Precision machining to improve the fitting degree of the sealing interface

The matching between the ball and the valve seat is precisely polished, allowing the floating ball to automatically compensate under pressure, thereby achieving a higher sealing class.

Reinforced bolt connection to enhance pressure-bearing capacity

The black high-strength bolts have uniform pre-tightening force, ensuring that the valve body remains structurally stable and not easily deformed under high pressure.

Standardized factory assembly to reduce human errors

Floating ball valve assemblies undergo unified assembly and testing in J-VALVES factories, avoiding the common problem of "different batches, different quality".

III. Is the Floating Ball Valve Suitable for Your System? What Are the Questions You Care About Most?

You may be troubled by the following questions:

The pressure in my working condition is high—can the floating ball valve withstand it?

J-VALVES floating ball valve assemblies feature a reinforced structural design, making them suitable for medium and high-pressure fluid control.

The temperature of my system changes greatly—will this affect the seal?

The floating structure can automatically compensate for the gap changes caused by thermal expansion and contraction, improving temperature resistance adaptability.

I need long-term stable operation—can consistent service life be guaranteed?

Due to the high precision of part processing and assembly consistency, the service life is significantly longer than that of low-standard ball valves.

IV. Why Are Enterprises Increasingly Inclined to Choose J-VALVES?

Since 2009, J-VALVES has been focusing on industrial valve manufacturing, with its advantages mainly reflected in:

Good batch consistency, suitable for project-based supply

Customizable assembly structures according to industry needs

Clear delivery standards and strong stability

Applicable to high-demand working conditions such as petroleum, chemical industry, natural gas, and energy

This means—you are not just getting a ball valve, but a "long-term reliable system component".

Conclusion: Does Your Pipeline Need a Truly Stable Floating Ball Valve?

If you are facing problems such as frequent leaks, high maintenance costs, and short valve service life, then J-VALVES assembled component floating ball valve may be the one that solves your pain points.

The real question is:

Are you still willing to pay for low-quality ball valves? Or should you choose a more stable and reliable industrial-grade solution?